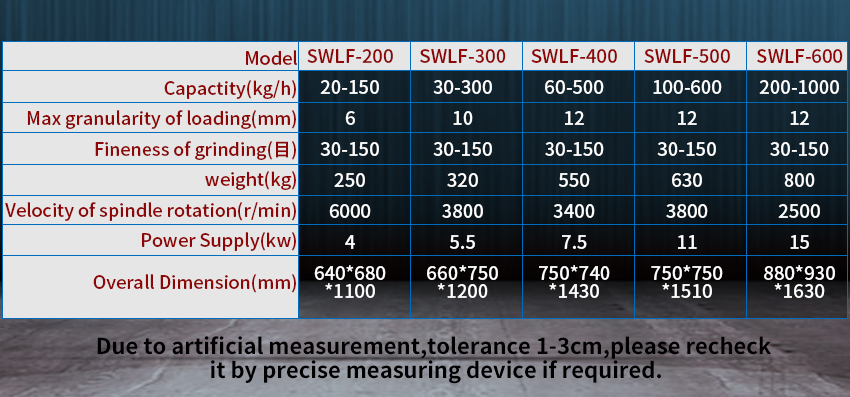

Xulang SWLF turbine pulverizer is mainly suitable for grinding materials with low hard feature in pharmaceutical, chemical, food (for example: ginger, chilli, sugar, salt, pepper, oil wheat, soybeans, star anise, cinnamon, dried vegetables etc ) .Range of fineness adjustment is from 30 to 150 mesh.The advantages include high yield, fine granularity, low noise, low energy consumption, simple maintenance, convenient installation etc. Especially,it fits to grind materials with low hard feature filling in oil, viscosity, heat sensitivity, fibre etc.

order

Xulang SWLF turbine pulverizer is mainly suitable for grinding materials with low hard feature in pharmaceutical, chemical, food (for example: ginger, chilli, sugar, salt, pepper, oil wheat, soybeans, star anise, cinnamon, dried vegetables etc ) .Range of fineness adjustment is from 30 to 150 mesh.The advantages include high yield, fine granularity, low noise, low energy consumption, simple maintenance, convenient installation etc. Especially,it fits to grind materials with low hard feature filling in oil, viscosity, heat sensitivity, fibre etc.

结构与工作原理 ( Structure and working principle )

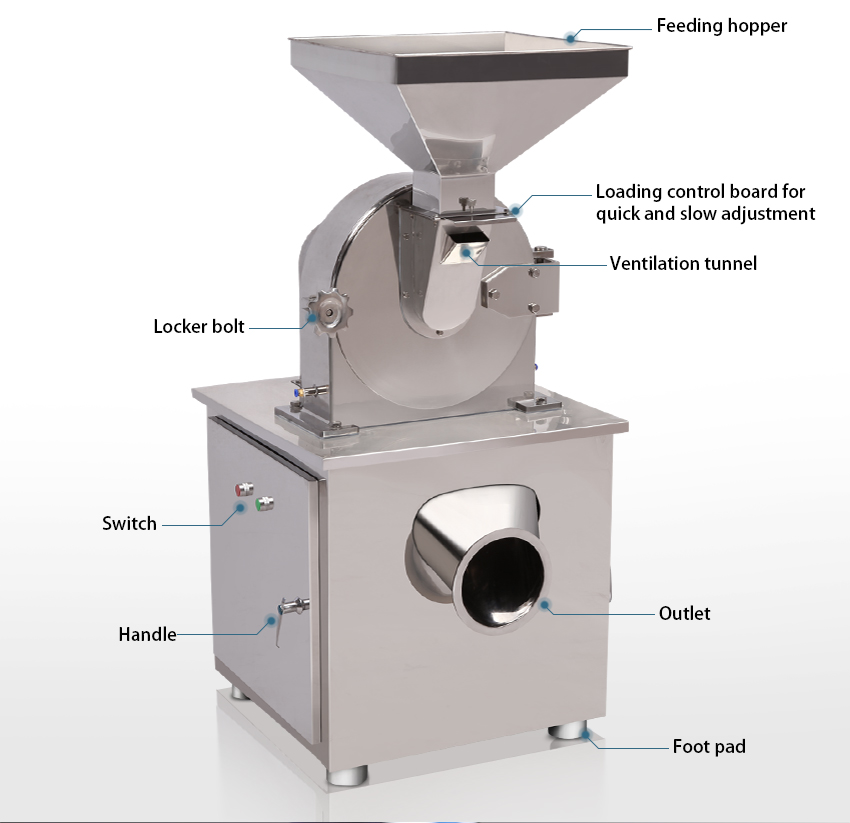

1. Structure : SWLF type turbine pulverizing machine mainly consists of these spare parts, such as machine shell, machine door, turbine, spindle, sieve, a belt pulley and a motor etc.

2.Working principle:

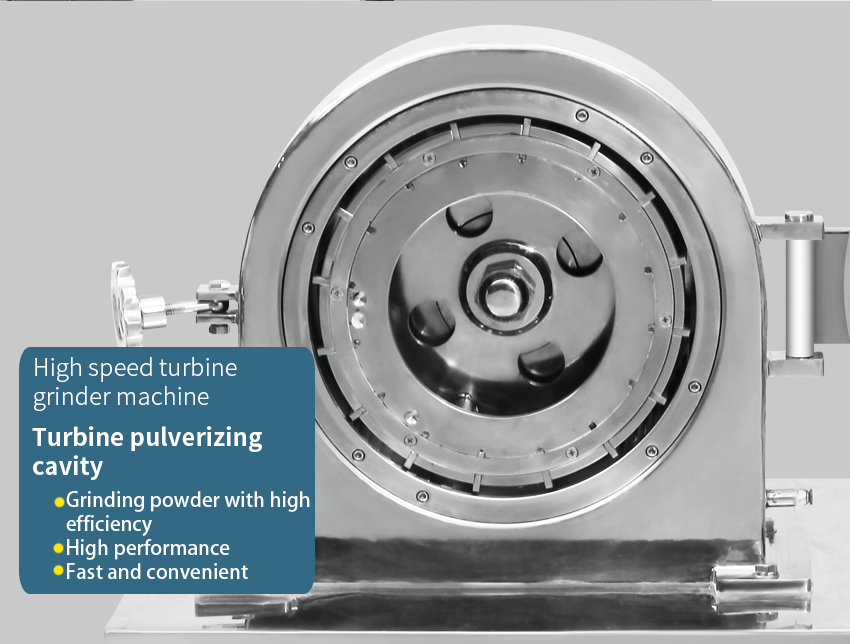

When the turbine grinding machine works, the motor drives the spindle and the turbine to rotate at high speed. The grinding bars fixed on the turbine and sieve circle combine the function of crushing and pulverizing.When the feeding materials enter the grinding cavity from the hopper,the feeding materials are pulled into the cavity by strong rotating airflow as well as the materials are always under a close friction,simultaneously,the materials are blown to interior impeller of turbine.At that time,these materials are pulverized between the impeller and turbine again.During the period of grinding materials,the turbine sucked a lot amount of air.These air can make the machine cool,improve to grind the materials and transmit fine materials.The fineness of grinding powder depends on the feeding material feature and the size of sieve,the passing amount of feeding materials and air.

3.The bearing components of SWLF turbine mill equips with a special labyrinth seal.The seal can effectively prevent the dust into the bearing cavity, thereby it can prolong the life of the shaft. A silicon rubber sealing ring is covered inside the machine door.Due to the sealing ring,there is no dust suffusing in the air and no pollution in operation space.

Edward Lu

Cellphone(手机): 0086 18027476645

Wechat(微信): 18027476645

Email(邮箱): xulangjixie@188.com